UHMWPE

Ultra-high molecular weight polyethylene (UHMWPE) is a type of engineering plastic that is known for its exceptional strength, durability, and resistance to wear and tear. It is a thermoplastic material that is composed of very long chains of polyethylene molecules, which gives it its unique mechanical properties.

UHMWPE is commonly used in a wide range of industrial applications, including as a lining material for hoppers, chutes, and other equipment that handles abrasive materials. It is also used in applications where high impact resistance is required, such as in the manufacturing of gears, bearings, and conveyor components.

One of the key advantages of UHMWPE is its low coefficient of friction, which makes it an ideal material for use in applications where sliding or rotating parts are involved. It is also resistant to chemicals, moisture, and UV radiation, which makes it suitable for use in harsh environments.

In addition to its mechanical properties, UHMWPE is also non-toxic and FDA-compliant, which makes it safe for use in food processing and medical applications. Overall, UHMWPE is a versatile and reliable engineering plastic that is widely used in a variety of industries due to its exceptional properties and performance characteristics

Please contact us if you would like more information about our UHMWPE.

PTFE

The heat stability and chemical resistance of PTFE are remarkable. It also has strong electrical resistance, a non-stick surface, and excellent sliding properties. Its use is nevertheless restricted to applications that require its thermal and wear-based properties due to its poor mechanical strength and stiffness.

PTFE is used for sliding applications and is available in sheets and rods, especially in environments where the component can be susceptible to chemical stress. PTFE can be moulded into various shapes and sizes, making it an ideal material for manufacturing different types of parts for example: plain bearings, slide plates, seal rings, washers, the food sector, and others. Please contact us if you would like more information about our PTFE.

Oil-Filled Nylon

For industrial applications that move slowly and are heavily loaded, oil filled nylon is a good choice. The internally lubricating properties improve wear resistance against traditional nylon. Please contact us if you would like more information about our Oil Filled Nylon.

Graphite Filled Nylon

Graphite-filled nylon provides good early wear and rubbing/sliding qualities in both dry and wet applications, as well as strong chemical resistance to corrosive environments. Please contact us if you would like more information about our Graphite Filled Nylon.

PETP

We offer PETP (Polyethylene Terephthalate), which is a high-performance engineering plastic used in various industrial applications. PETP has excellent dimensional stability, high tensile strength, toughness, superior stiffness, and low coefficients of friction. We provide extruded PETP rods, sheets, tubes, and machined components according to our clients’ specifications. Our PETP products are available in natural white and black colours. Please contact us if you would like more information about our PETP.

PVC

PVC material is a semi-crystalline plastic with excellent rigidity and durability that is simple to produce and maintain a tight tolerance in. PVC is a widely accessible and cost-effective solution for many industries. PVC is also available in a variety of colors, making it ideal for uses where aesthetics are more important. Please contact us if you would like more information about our PVC.

Acrylic

Acrylic materials are commonly used for aesthetic purposes because of their highly polished surfaces, transparency, and availability in a broad range of dazzling hues and finishes. Acrylic is also an excellent material for signage due to its weathering and UV resistance. Please contact us for more information about our acrylic products.

Polycarbonate

In order to prevent deterioration, polycarbonate (PC) blends impact resistance with a UV-resistant surface treatment on one side. Polycarbonate offers persistent clarity in a wide range of environments and weather conditions, extending service life and lowering life-cycle material costs. Please contact us if you would like more information about our polycarbonate.

Acetal

Acetal offers good electrical properties and is easy to produce with precise tolerances. Copolymers have improved chemical resistance at higher temperatures. Acetal also exhibits excellent fatigue and creep resistance, tensile and flexural strength. Homopolymer has slightly better mechanical properties and a higher level of surface hardness, although it may be prone to centreline porosity. Please contact us if you would like more information about our ACETAL.

HDPE

High density polyethylene (HDPE) is a well-liked plastic material for a range of applications since it is sturdy, long-lasting, light, and chemically resistant. HDPE is utilized in a variety of applications and industries that require high tensile strength, low moisture absorption, chemical and corrosion resistance, and excellent impact resistance. Please contact us if you would like more information about our HDPE.

Nylon6

Nylon 6 is an excellent technical material and a member of the polyamide family. It is extensively used in daily life due to its outstanding thermal resistance, weatherability, and chemical resistance, as well as its antistatic, wear-resistant, flame-retardant, rigidity, and toughness. It also has excellent electrical and mechanical properties.

Nylon 6 is widely used in various industries, such as automotive and locomotive, sports, electronics, mechanical components, and food packaging. Please contact us if you would like more information about our NYLON6.

Polypropylene

Polypropylene is a versatile and cost-effective engineering plastic that offers excellent chemical resistance, durability, and heat resistance. It is widely used in various industrial and consumer applications due to its high impact strength, stiffness, and fatigue resistance. Polypropylene is an excellent choice for applications that require high temperature resistance, such as automotive components, food packaging, medical equipment, and electrical components. Our company provides high-quality Polypropylene materials in various forms, including sheets, rods, and tubes, tailored to meet the specific needs of our customers. Please contact us if you would like more information about our polypropylene.

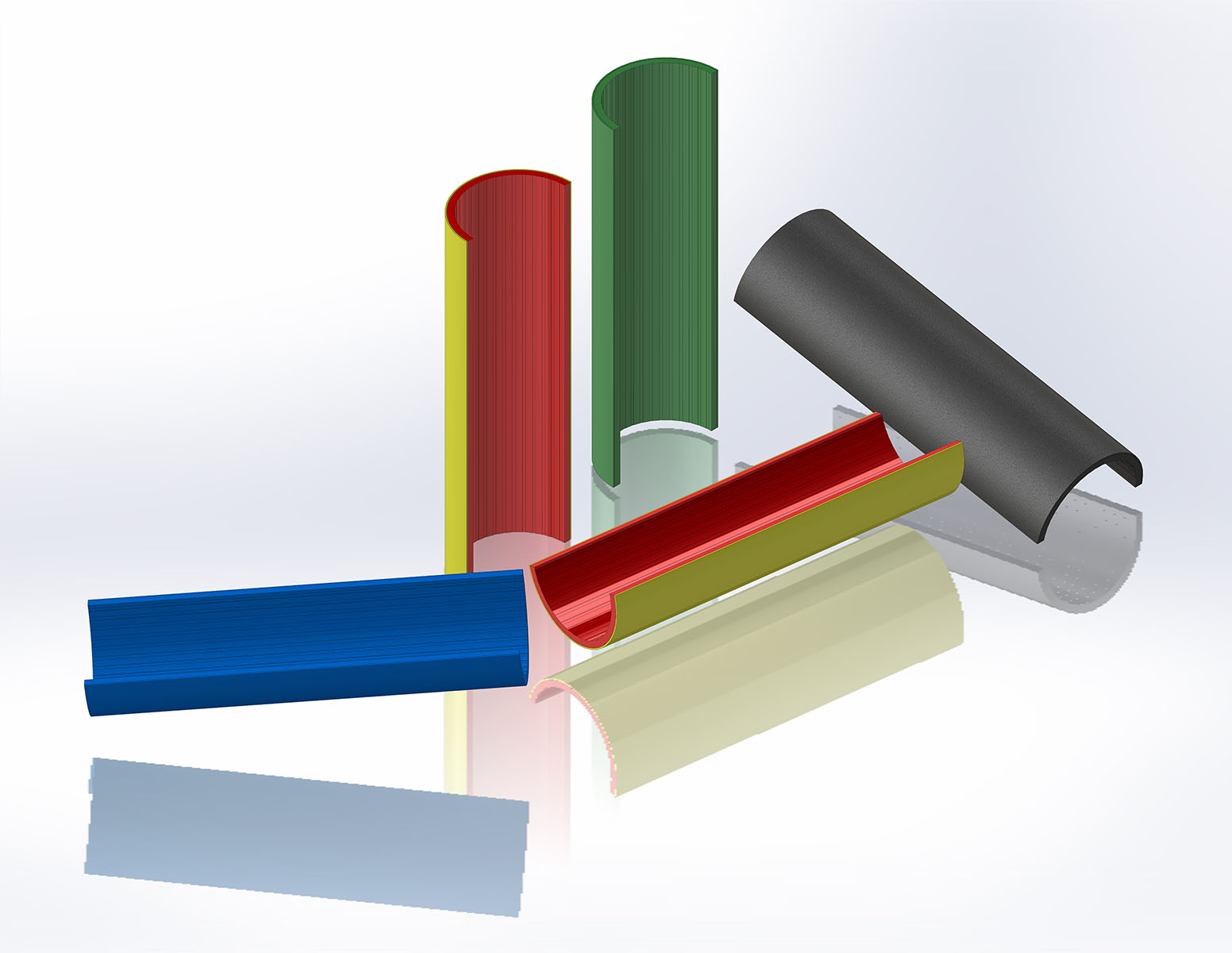

Auger Through Liner

Our Auger Through Liners are designed to provide superior protection and performance for your auger systems. We offer customized sizes with rolled options to ensure a perfect fit for your specific applications. Available in a variety of striking colours, including white, black, yellow, red, and green, our liners come with dual-colour options on both sides. This feature not only enhances visibility but also allows for easy monitoring of wear and tear.

By utilizing two colours—one for the outer surface and another for the inner surface—users can quickly assess the condition of the liner. As the inner surface experiences wear due to working conditions, the colour change provides a clear indication of when maintenance is needed, helping you avoid unexpected downtime. For those seeking a more uniform appearance, we also offer single-color options. Crafted from high-quality materials, our Auger Through Liners ensure durability and maintain efficient material flow, making them an essential component for any auger system.