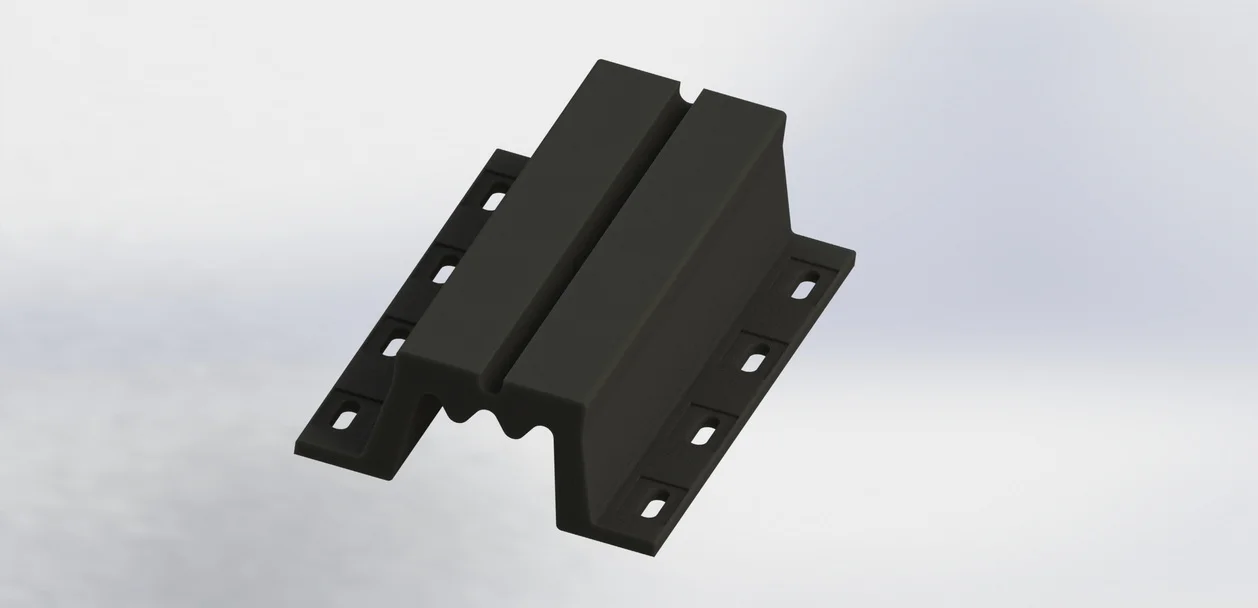

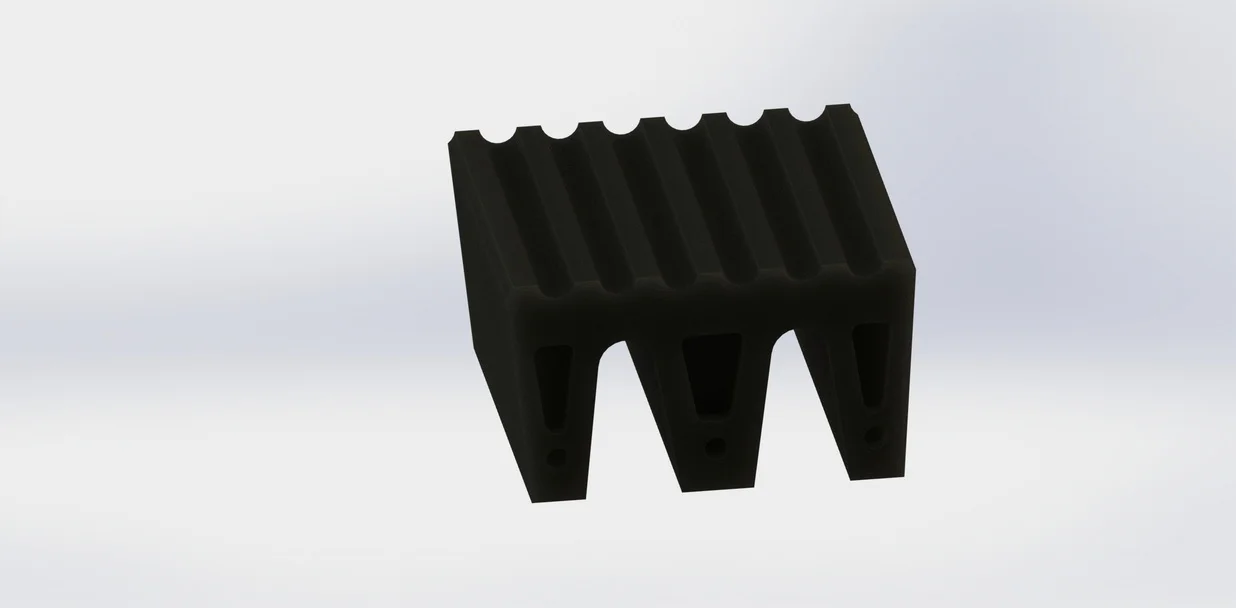

Rubber Fender M Type

M fenders are a type of rubber fender that is incredibly strong. They are commonly used at the bow or stern of vessels as well as at the corners of docks and pontoons. Due to their flexibility, these fenders can easily follow the shape of a bow or stern. The M shaped contact surface of these fenders is large and flexible, which helps to reduce friction. Compression moulding is used to create M type rubber fenders, which are lighter than W fenders and can be installed on a short radius. If you would like more information about our Rubber Fender M Type, please do not hesitate to contact us.

Features of Rubber Fender M Type

- Easy installation: Rubber fenders are relatively easy to install and can be fixed to a variety of surfaces, including concrete, steel, and timber.

- Low maintenance: Rubber fenders require minimal maintenance and can withstand harsh weather conditions and exposure to saltwater.

- Cost-effective: Rubber fenders are generally more cost-effective than other types of fender systems, such as steel or timber fenders, due to their low maintenance requirements and long lifespan.

Rubber Fender Specifications

| Specification | W | A | B | F | K | L | D | L1 | P | Q | Bolts | |||||

| 1000 | 3000 | 3500 | ||||||||||||||

| E | ||||||||||||||||

| 250H | 625 | 170 | 535 | 330 | 130 | 125 | 28 | 865 | 680 | 620 | 790 | 715 | 673 | 32 | 64 | M24 |

| 300H | 750 | 204 | 640 | 396 | 140 | 150 | 33 | 870 | 685 | 625 | 790 | 715 | 674 | 35 | 70 | M30 |

| 400H | 1000 | 272 | 870 | 528 | 150 | 200 | 44 | 900 | 700 | 635 | 800 | 725 | 680 | 41 | 82 | M36 |

| 500H | 1250 | 340 | 1090 | 660 | 160 | 250 | 55 | 930 | 715 | 645 | 810 | 730 | 686 | 47 | 94 | M42 |

| 600H | 1500 | 408 | 1310 | 776 | 170 | 300 | 66 | 960 | 730 | 655 | 820 | 740 | 692 | 58 | 116 | M48 |

| 800H | 2000 | 544 | 1740 | 1035 | 180 | 400 | 88 | 1040 | 770 | 680 | 845 | 700 | – | 68 | 136 | M64 |

| 1000H | 2480 | 670 | 2180 | 1294 | 200 | 500 | 110 | 1100 | 800 | 700 | – | – | – | 68 | 136 | M64 |

Applications

Rubber fenders M- Type are widely used in marine and shipping industries for various applications, including:

- Port and harbour protection: Rubber fenders are commonly used to protect port and harbour structures, such as quay walls, piers, and jetties, from damage caused by berthing vessels.

- Ship-to-ship transfer: Rubber fenders are used during ship-to-ship transfers to prevent damage to the vessels involved.

- Offshore structures: Rubber fenders are also used to protect offshore structures, such as oil rigs and wind turbines, from damage caused by waves and currents.

- Ferry terminals: Rubber fenders are used in ferry terminals to protect the vessels and the terminal structures during docking and berthing.

- Yacht clubs and marinas: Rubber fenders are used in yacht clubs and marinas to protect boats and yachts from damage caused by contact with the dock or other vessels.

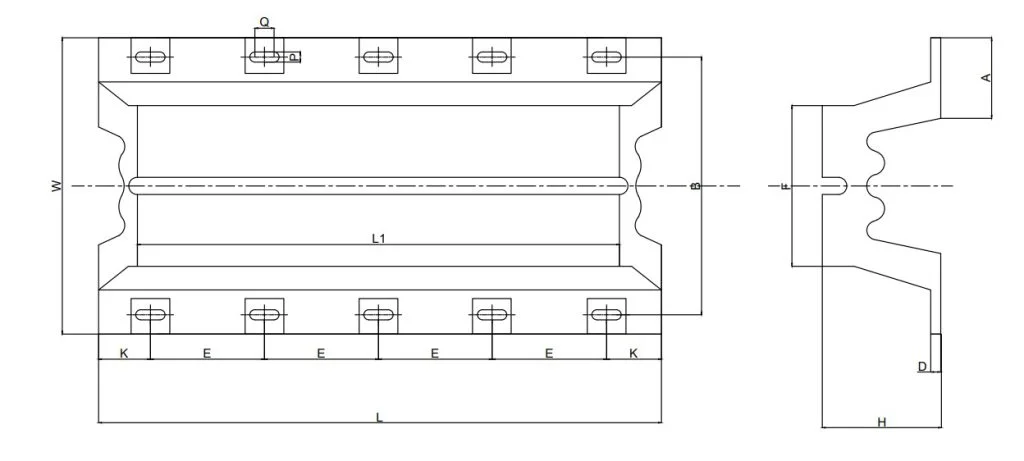

Rubber Fender U-Type

A marine fender known as a U-type rubber fender is made to prevent collisions between ships and docks, piers, and other vessels. Because of its U-shaped cross-section, which allows it to collapse when in contact with a vessel and absorb impact, it is known as a U-type fender. This reduces the risk of damage to the vessel or the structure it is colliding with. In order to fit a variety of applications, U-type rubber fenders are normally constructed from high-quality rubber compounds that are resistant to weathering and abrasion. They are also offered in a variety of sizes and shapes. They have demonstrated to be effective in ports, harbours, and other marine situations where vessels are often docking or manoeuvring. Please contact us if you would like more information about our Rubber Fender U-Type.

Features Of Rubber Fender U Type

- Energy absorption: Rubber fenders are designed to absorb energy during a collision, reducing the impact force and protecting both the vessel and the dock or structure.

- Low reaction force: Rubber fenders also have a low reaction force, which means that they provide a soft and gentle contact between the vessel and the dock or structure.

- Durable material: Rubber fenders are typically made of high-quality, long-lasting rubber material that is resistant to wear, tear, and corrosion.

- Easy installation: Rubber fenders are relatively easy to install and can be fixed to a variety of surfaces, including concrete, steel, and timber.

| U Type Rubber Fender Specification | ||||||||||

| Specification | H | h | B | B1 | C | Q | e | f | d | g |

| U300H×1500L | 300 | 35 | 540 | 430 | 150 | 600 | 60 | 90 | 32 | 80 |

| U300H×900L | ||||||||||

Performance: –

| Reaction Force | Unit | Measured data | |

| Compressive Deflection | 50.00% | Tons | 33 |

| Compressive Deflection | 62.50% | Tons | 40 |

| Energy Absorption | |||

| Compressive Deflection | 50.00% | Tons | 1.6 |

| Compressive Deflection | 62.50% | Tons | 2.9 |

Applications

Rubber fenders are widely used in marine and shipping industries for various applications, including:

- Port and harbour protection: Rubber fenders are commonly used to protect port and harbour structures, such as quay walls, piers, and jetties, from damage caused by berthing vessels.

- Ship-to-ship transfer: Rubber fenders are used during ship-to-ship transfers to prevent damage to the vessels involved.

- Offshore structures: Rubber fenders are also used to protect offshore structures, such as oil rigs and wind turbines, from damage caused by waves and currents.

- Locks and dams: Rubber fenders are used to protect locks and dams from damage caused by boats and ships passing through them.

Ferry terminals: Rubber fenders are used in ferry terminals to protect the vessels and the terminal structures during docking and berthing.

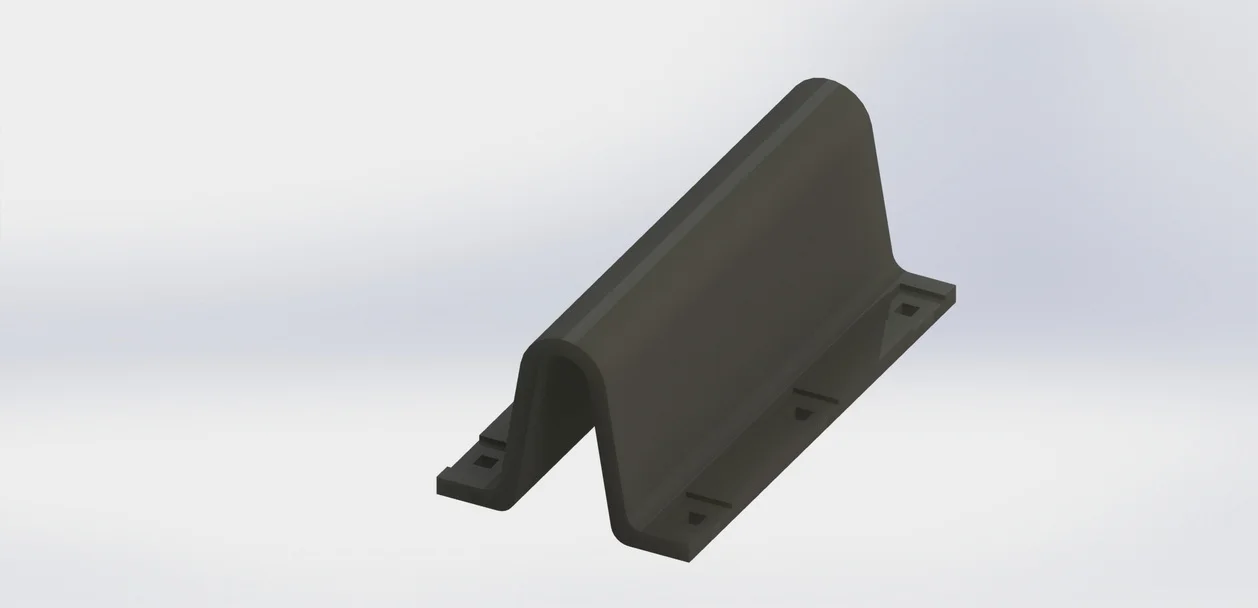

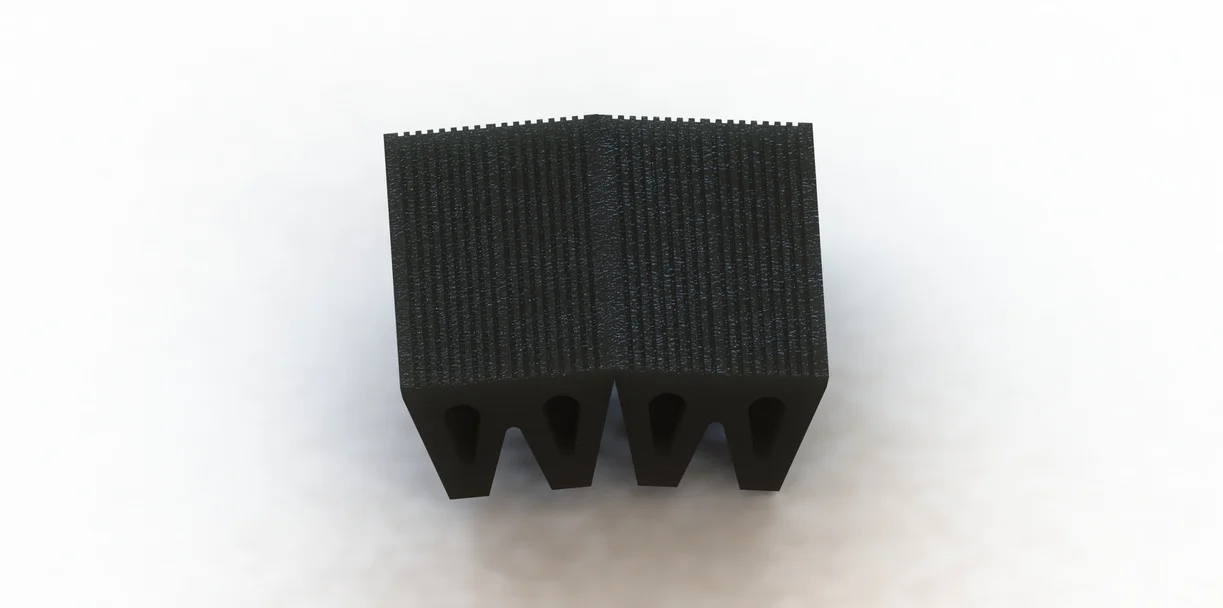

Rubber Fender W Type

There are two types of W-shaped rubber fenders those with two legs and those with three legs. These fenders have a broader face than super arch rubber fenders, resulting in lower hull pressure, more deflection, and a better energy-to-reaction ratio.

W-type rubber fenders can be used on the bow and stern of icebreakers, work boats, and tugboats. They can be easily attached using bolt rods and flexible legs, regardless of whether the radius is large or small. Please contact us if you would like more information about our Rubber Fender W Type.

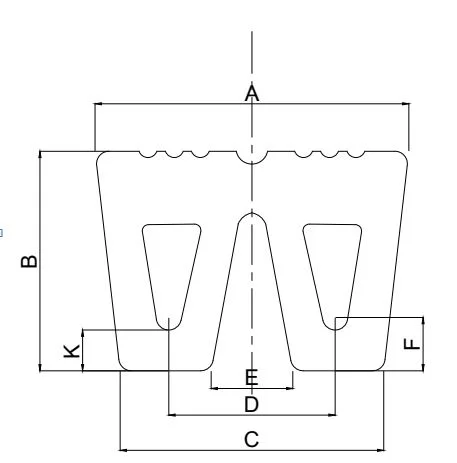

A. Rubber Fender W Type Two Legs Specifications

| Type | A | B | C | D | E | F | K | L |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| 320X200 | 320 | 200 | 280 | 180 | 100 | 67 | 50 | 3000 |

| 400X250 | 400 | 250 | 350 | 220 | 110 | 75 | 55 | 3000 |

| 480X300 | 480 | 300 | 426 | 268 | 146 | 85 | 65 | 3000 |

| 500X350 | 500 | 350 | 420 | 268 | 130 | 85 | 65 | 3000 |

| 500X450 | 500 | 450 | 420 | 268 | 146 | 100 | 80 | 3000 |

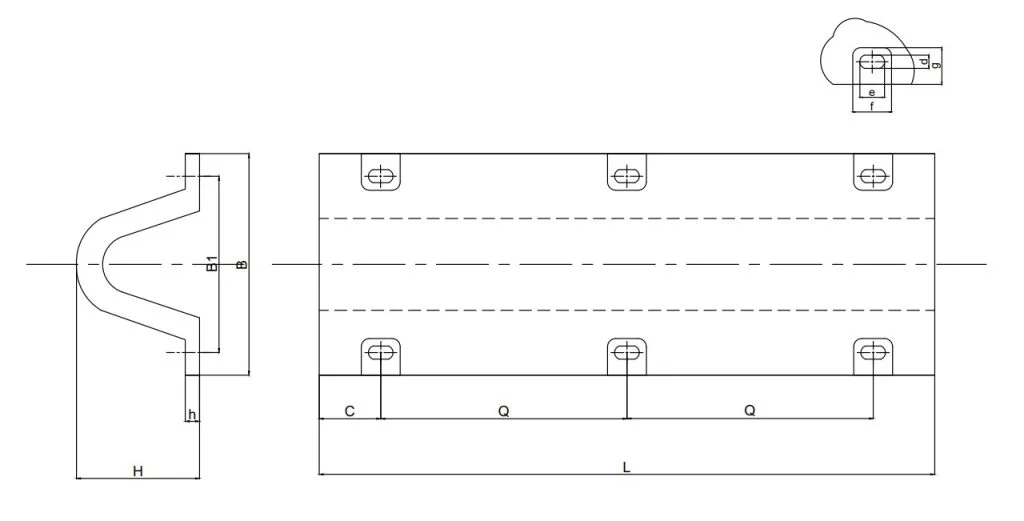

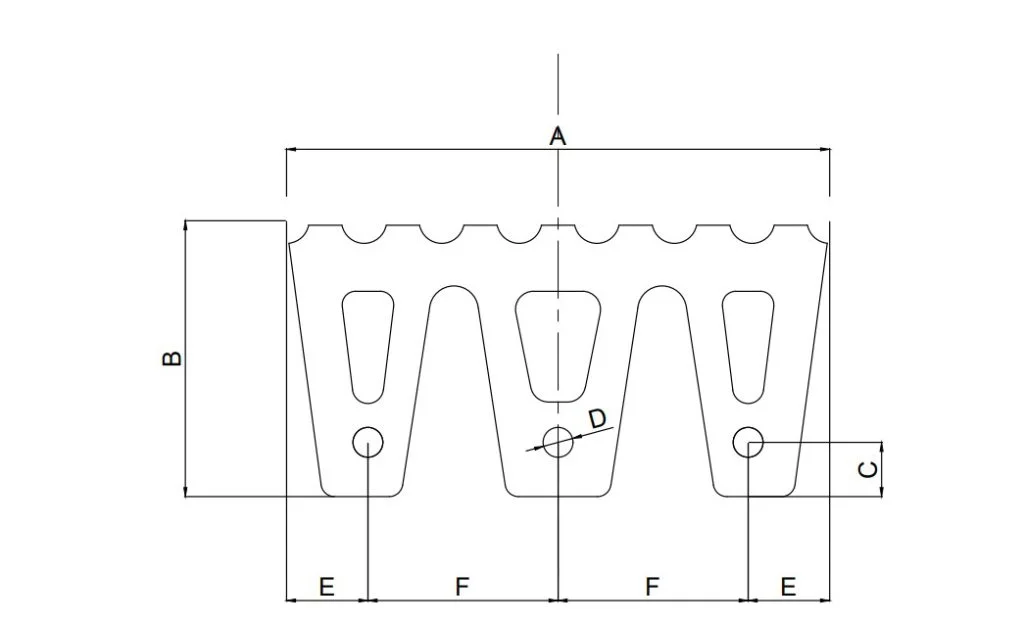

B. Rubber Fender W Type Three Legs Specifications

| Type | A | B | C | ΦD | E | F | L |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| M400 | 400 | 200 | 40 | 23 | 50 | 150 | 3000 |

| M500 | 500 | 250 | 50 | 27 | 60 | 190 | 3000 |

| M600 | 600 | 300 | 60 | 33 | 70 | 200 | 3000 |

Features of Rubber Fender W Type

- Energy absorption: Rubber fenders are designed to absorb energy during a collision, reducing the impact force and protecting both the vessel and the dock or structure.

- Low reaction force: Rubber fenders also have a low reaction force, which means that they provide a soft and gentle contact between the vessel and the dock or structure.

- Durable material: Rubber fenders are typically made of high-quality, long-lasting rubber material that is resistant to wear, tear, and corrosion.

- Easy installation: Rubber fenders are relatively easy to install and can be fixed to a variety of surfaces, including concrete, steel, and timber.

Applications

Rubber fenders are widely used in marine and shipping industries for various applications, including:

- Port and harbour protection: Rubber fenders are commonly used to protect port and harbour structures, such as quay walls, piers, and jetties, from damage caused by berthing vessels.

- Ship-to-ship transfer: Rubber fenders are used during ship-to-ship transfers to prevent damage to the vessels involved.

- Offshore structures: Rubber fenders are also used to protect offshore structures, such as oil rigs and wind turbines, from damage caused by waves and currents.

- Locks and dams: Rubber fenders are used to protect locks and dams from damage caused by boats and ships passing through them.

- Ferry terminals: Rubber fenders are used in ferry terminals to protect the vessels and the terminal structures during docking and berthing.

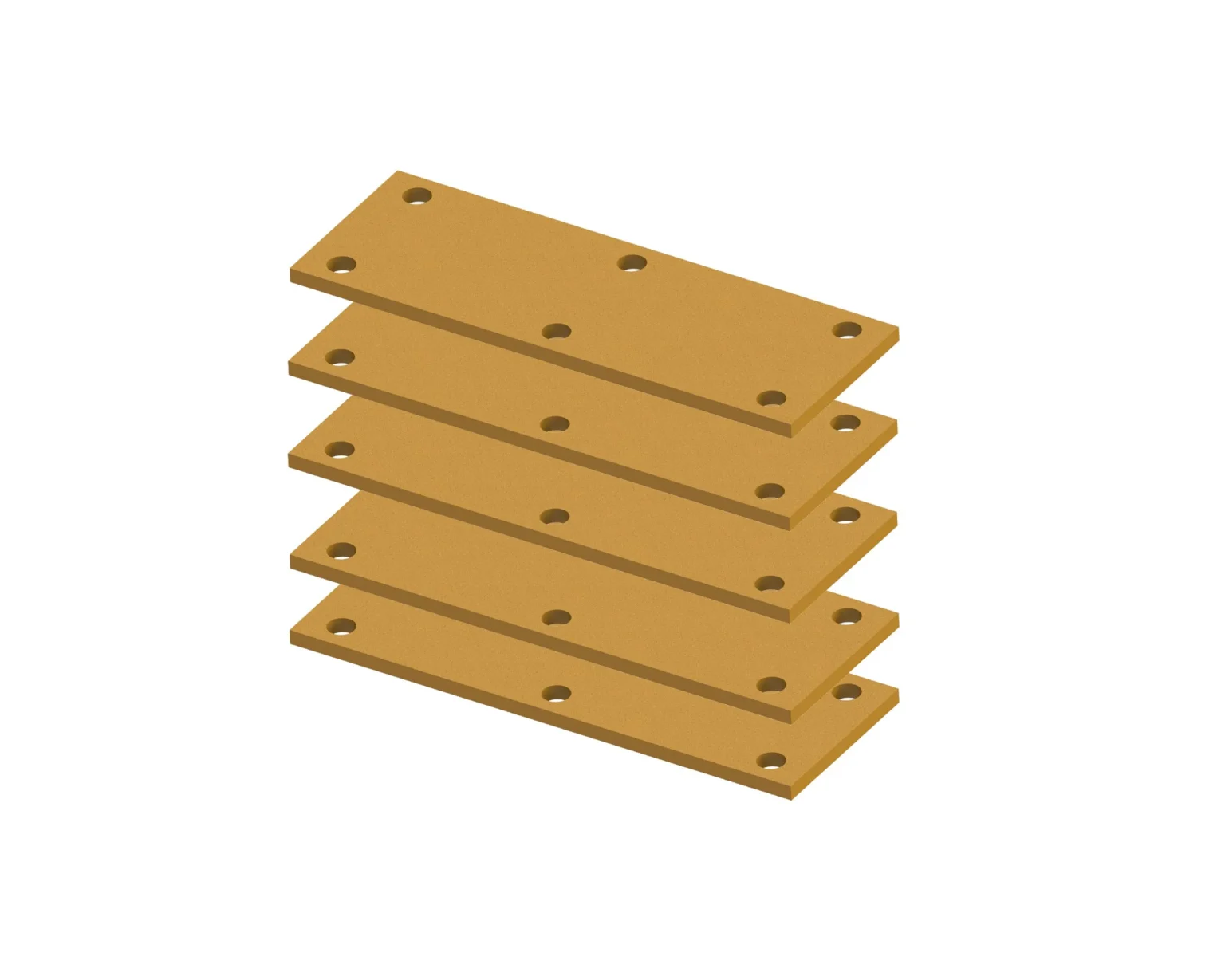

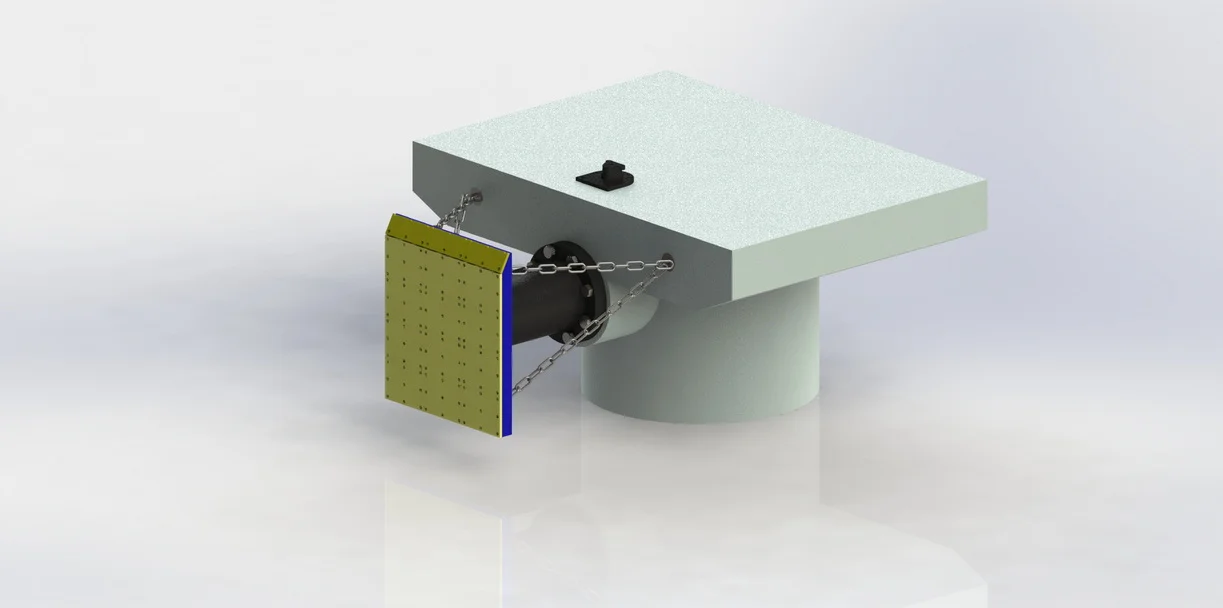

Rubber fender UHMWPE Facial Pad

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) facial pads are often used in conjunction with rubber fenders to provide additional protection to vessels and structures during berthing operations. These pads are made from a high-strength, low-friction material that helps to reduce the impact force and minimize damage during collisions. Please contact us if you would like more information about our Rubber Fender UHMWPE Facial Pad.

Rubber fender UHMWPE facial pad Specification

The specifications of UHMWPE facial pads used with rubber fenders can vary depending on the specific application and requirements. However, some common specifications of UHMWPE facial pads include:

- Material: UHMWPE facial pads are made from ultra-high-molecular-weight polyethylene, which is a tough and durable material that is resistant to wear, tear, and abrasion.

- Thickness: The thickness of UHMWPE facial pads can vary depending on the application and requirements, but is typically in the range of 10 to 50 mm.

- Dimensions: UHMWPE facial pads are available in various dimensions and shapes to suit different types of rubber fenders and berthing applications.

We Offer as your customized size as per your demands

Applications:

UHMWPE facial pads are typically used in marine and shipping industries in conjunction with rubber fenders to provide additional protection to vessels and structures during berthing operations. Some common applications of rubber fender UHMWPE facial pads include.

- Port and harbour protection: UHMWPE facial pads are commonly used in ports and harbours to protect quay walls, piers, and other structures from damage caused by berthing vessels.

- Ship-to-ship transfer: UHMWPE facial pads are used during ship-to-ship transfers to prevent damage to the vessels involved.

- Offshore structures: UHMWPE facial pads are also used to protect offshore structures, such as oil rigs and wind turbines,

Marine Fender Plastic Pad

Although it may not be as widely known as some other engineering plastics, UHMWPE is a super material that can outperform its relatives in a number of key areas. UHMWPE combines good mechanical qualities, even in cold environments, remarkable abrasion resistance, superior impact resistance, non-sticking and self-lubricating properties, and excellent mechanical properties. UHMWPE products lessen vibrational and impact noise. It is a self-lubricating substance that is resistant to chemicals, corrosion, and wear. It is also food safe. The burden is little. Life is superior to steel. Stainless steel and carbon steel have wear resistance that is 3–7 times greater. Please contact us if you would like more information about our Marine Fender Plastic Pad.

UHMWPE Characteristics

- UHMWPE demonstrates almost no water absorption.

- Low frictional resistance

- Corrosion-proof

- Resistant against abrasion and impact

- Resistance to wear

- Excellent liner material for applications involving industrial material handling.

Specifications

- UHMWPE Sheet

- UHMWPE exhibits virtually no water absorption.

- Thickness:3 mm-380mm

- Max Width: 2300mm

- Length: Any length

- Low coefficient of friction

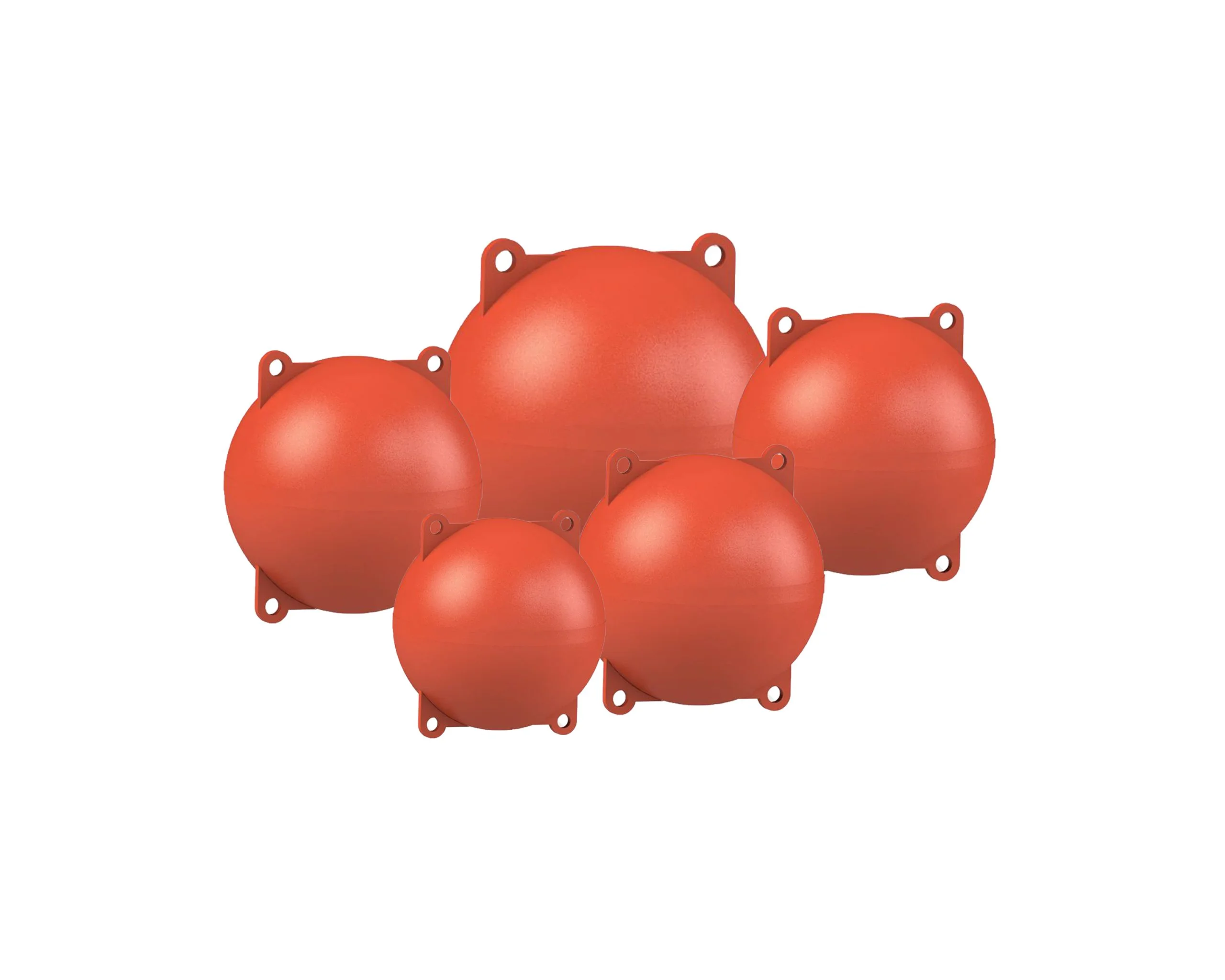

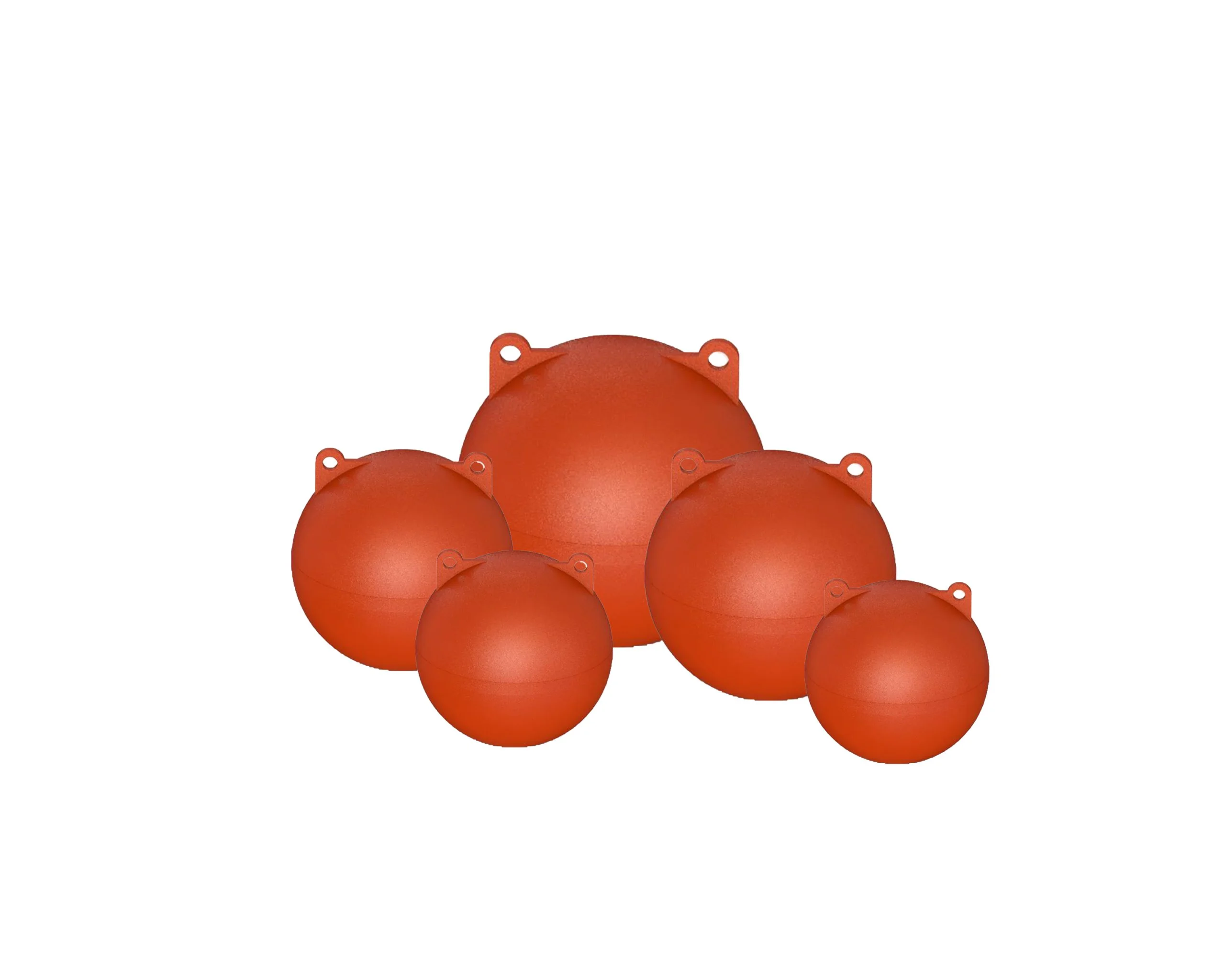

ABS Fishing Float

Our company offers a wide range of sturdy, deep-water resistant ABS floats that are a fantastic option for aquaculture and marine fishing. We provide fishing floats in a variety of colors and materials with diameters ranging from 150 to 600 millimeters. To meet the diverse needs of our customers, we offer customized services for the floats. If you would like more information about our ABS Fishing Floats, please don’t hesitate to get in touch with us.

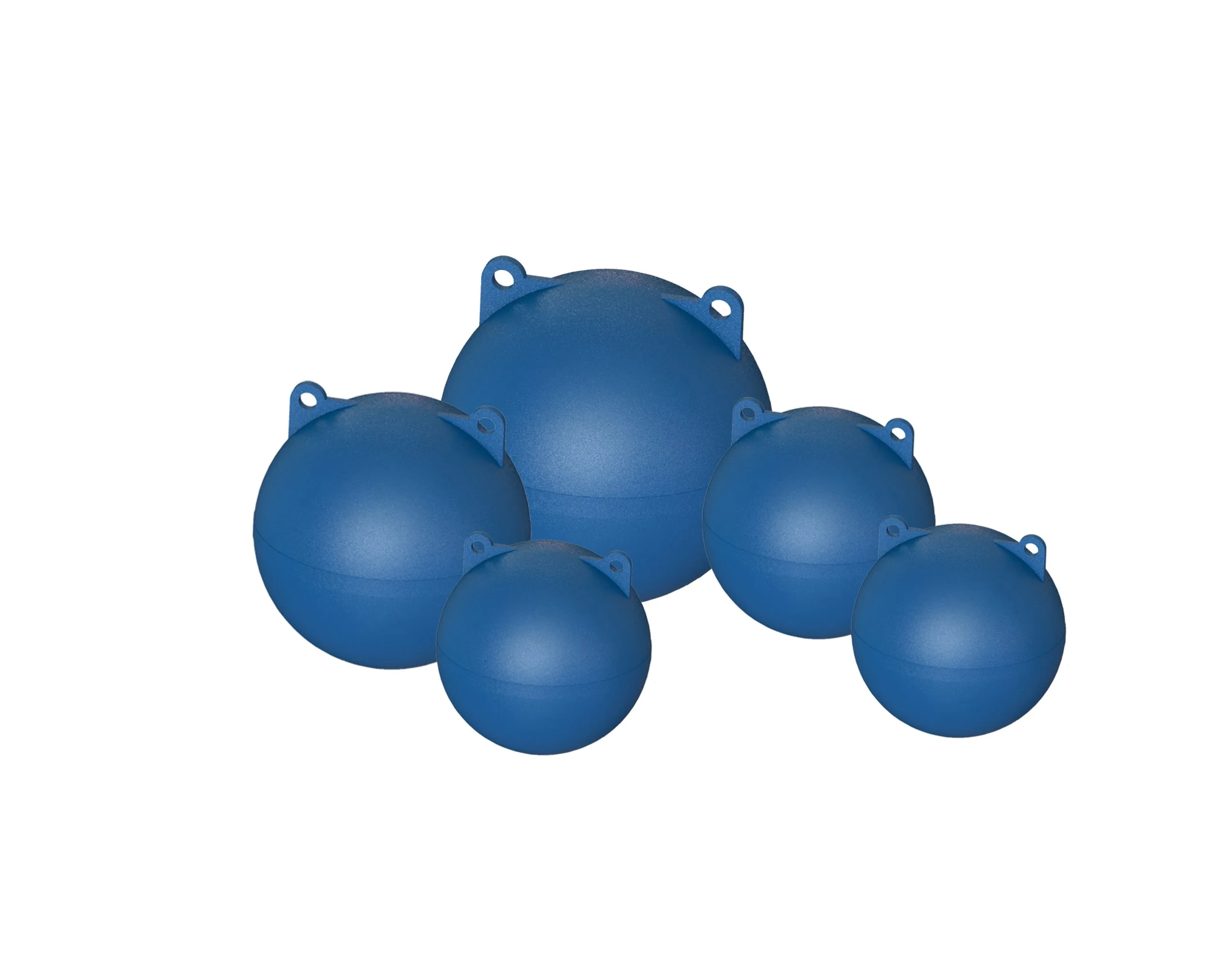

Plastic Fishing Net Float

Our company supplies high-quality plastic fishing net floats with either two or four ears. These floats feature high-pressure resistance and can be utilized in water depths of up to 100 meters. We offer both generic products and custom-supplied products to meet your specific needs. Please feel free to contact us if you would like more information about our plastic fishing net floats.”

Specifications

| Colour | Material | Net Weight(kg) | Diameter

(cm) |

Buoyancy(kg) | ‘Ears’ Quantity | Usage |

| Red | ABS | 1.75 | 30 | 8 | 4 | High-pressure deep-water net float |

| White | ABS | 0.175 | 14 | 4 | 4 | |

| White | ABS | 0.55 | 22 | 6 | 4 |

Note: There are other types of material used to make fishing net floats, including PVC, EVA, and PE

Deep Sea Trawl Float

Regarding deep-sea trawl float is made of sturdy ABS material and features two ears. It is frequently used in combination with fishing nets, such as trawl nets, for deep-sea fishing.

Features of ABS plastic fishing floats</strong

- Impact resistance

- Ageing resistance

- High pressure resistance

- And more

These floats are the best fishing gear for deep-sea fishing.

Specifications

- Material: ABS plastic

- Net Weight: 1.75kg

- Buoyancy: 8kg

- Pressure Depth: 100m

- Diameter: 300mm

- Colour: Red/White/Customized

- Shape: Round

The specifications listed above are merely for reference. We offer fishing floats in every specification, including fishing net floats made of PVC, EVA, PE, and ABS. Please feel free to contact us if you would like more information about our deep-sea trawl float.