Welcome to our comprehensive guide to Wedge Wire Screens! Discover everything you need to know about these versatile and effective screening solutions right here.

Wedge wire screens are vital components used in various industries for solid-liquid and solid-gas separation processes. Our website provides information on the supply and applications of wedge wire screens. Whether you’re an engineer, researcher, or industry professional, our content caters to all levels of expertise. We offer customized screen sizes based on client requirements and provide materials such as ferrite, austenite, duplex, carbon steel, and others.

Explore our informative articles covering topics such as:

Introduction to Wedge Wire Screens: Learn about the unique design and structure of wedge wire screens and how they differ from other types of screens.

Applications and Industries: Understand where wedge wire screens are used, from water treatment and food processing to mining, well applications, and petrochemical industries.

Advantages and Benefits: Discover the benefits of using wedge wire screens, including high strength, precise sizing, and easy maintenance.

Customization and Design Options: Explore the various customization options available for wedge wire screens to suit specific project requirements.

Whether you’re seeking technical specifications, project inspiration, or troubleshooting advice, our website is your go-to resource for all things related to wedge wire screens. Join our community and stay updated with the latest developments in this essential technology.

We supply a variety of screens including Wedge Wire Screen Panels, Support Grids, Sieve Bends, Screen Cylinders, Screen Baskets, Filter Nozzles, Lateral Assemblies, Resin Traps, Flat Screens and Sand Screens.

Filter Nozzles

Discover high-performance wedge wire filter nozzles designed for efficient filtration applications. Our precision-engineered filter nozzles offer superior strength, durability, and clog resistance for a wide range of industrial and municipal water treatment processes. Different wedge wire sizes and slot configurations cater to various filtration classes. We offer four types of nozzles: Single-head filter nozzles, Double-head filter nozzles, Long-handle filter nozzles, and Plate-type filter nozzles. These versatile nozzles find applications in water treatment equipment and installations, widely used in power plants, petroleum, chemical, pharmaceutical, food, and other industries. Our materials include stainless steel and various alloy options. Explore our selection of custom-designed filter nozzles crafted from premium materials to meet your specific filtration requirements.

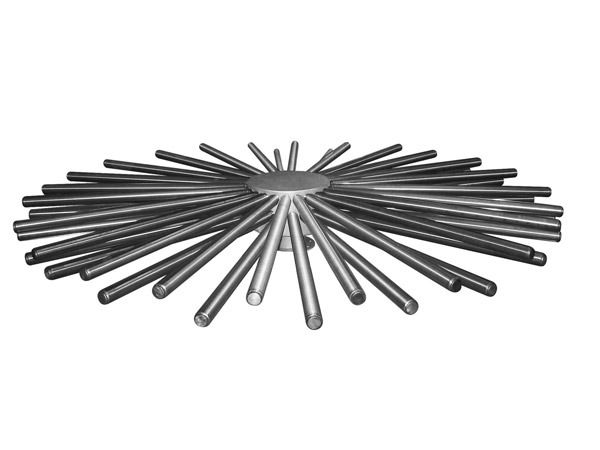

Lateral Assemblies

Explore our innovative wedge wire lateral assemblies designed for superior filtration. We specialize in supplying and delivering high-quality filtration solutions tailored to your specific needs. Our wedge wire lateral assemblies are engineered for optimal performance and durability, providing exceptional filtration efficiency in a wide range of industrial and municipal drainage applications. Whether you need custom configurations or standard sizes, our expert team ensures precision engineering and reliable service. Our materials include stainless steel and various alloy options. Discover how our wedge wire lateral assemblies can elevate your filtration processes.

Sand Screens

Wedge wire sand screens are essential components in oil drilling operations, commonly employed during early completion or oil production to manage sand. Their primary purpose is to remove small stones or gravel from the oil, ensuring the purity of the oil. The wedge wires integrated into these screens form V-shaped openings between the slots, facilitating efficient oil-water filtration. The continuous wrapping of wedge wires around the pipe creates a uniform, high-density gap, which guarantees an open screen area and prevents blockages. This innovative design aids in preventing sediment accumulation, thereby enhancing production efficiency and extending oil well pump inspection cycles.

Our company specializes in providing high-quality filtration solutions tailored to meet your specific needs. Our meticulously crafted wedge wire sand screens offer superior performance and durability, delivering exceptional filtration efficiency across various industrial and environmental applications. Whether you require custom sizes or standard configurations, our experienced team ensures precise engineering and reliable service. Discover how our wedge wire sand screens can optimize your filtration processes. Contact us today to discuss your requirements and leverage our expertise in filtration technology.

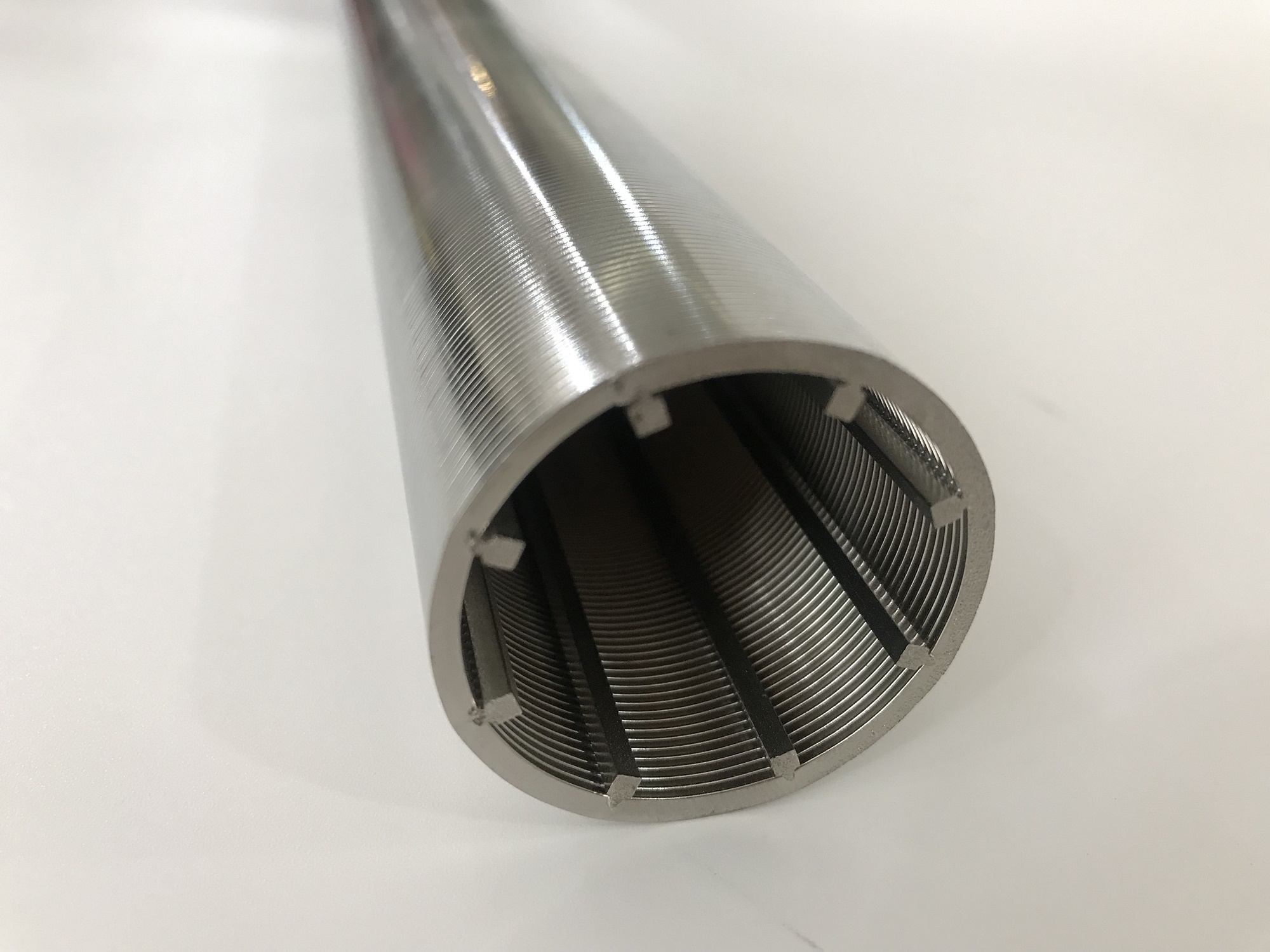

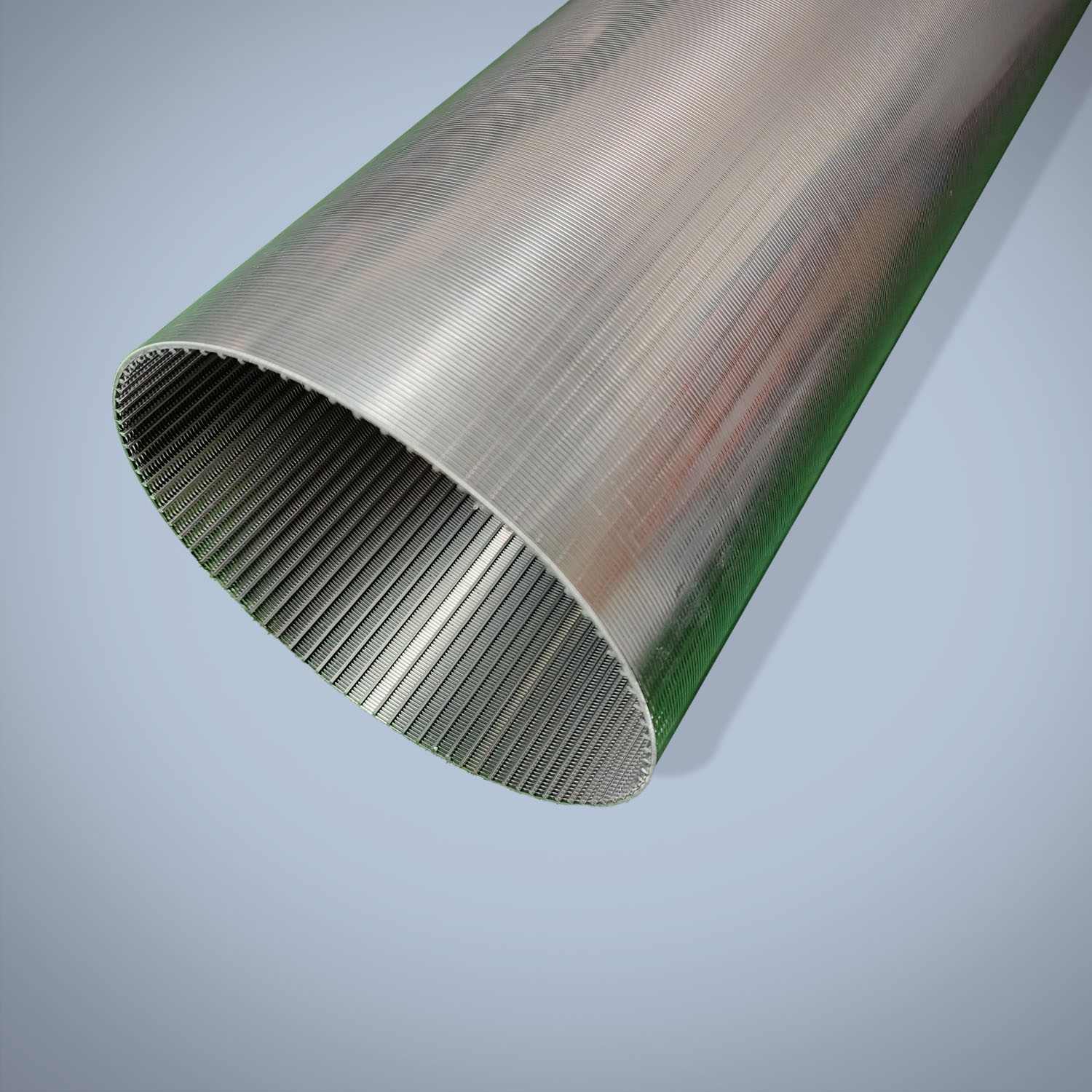

Wedge wire Screen Cylinders

Wedge wire screen cylinders are designed with a spiral profiled working surface supported by wires arranged along the axis of the cylinder construction. This unique design allows for optimized collection and distribution of fluids, eliminating the need for perforated inner tubes. Our Wedgewire screen cylinders are utilized in various applications including portable water treatment, ion exchange processes, oil refining, and more. Explore our range of Wedgewire screen cylinder solutions to discover how we can elevate your filtration processes. We offer customized sizes of screens, so please explore our website and let us know your requirements.

Wedge wire Screen Baskets

The Screen Basket is a crucial metal-slotted centrifugal component used for screening and filtering within centrifuge systems.

Comprised of an upper flange, lower flange, reinforcing ribs, reinforcing rings, and a stainless-steel cone mesh cylinder, the Screen Basket features sieve bars arranged along its cone-shaped structure. These bars are wedge-shaped to prevent screen clogging. Wedge sieve bars and support strips made from stainless-steel wires are meticulously welded to form fan-shaped screen meshes, which are then assembled into a cone mesh cylinder. The sieve slots typically range from 0.3 mm to 1 mm, with customization available upon request. The Screen Basket is securely attached to the main body using bolts through holes in the upper or lower flange.

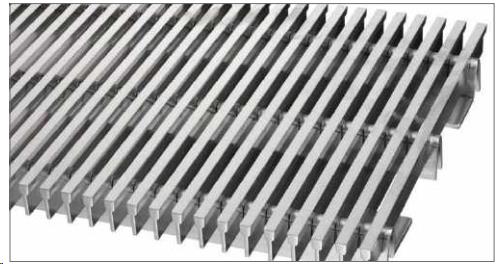

Wedge Wire Screen Panels

We specialize in supplying welded wedge wire screens where profile wires are precisely welded to support rods at a 90-degree angle using advanced modern welding technology. This method ensures the construction of screens with precise slot sizes, capable of handling heavy loads while maintaining exceptional durability. Our innovative technology solutions encompass high-quality welding techniques, a diverse range of profile wire options, and the ability to customize screens with multiple slot sizes and support distances, resulting in superior flatness across the sieve surface. The benefits of our screens are manifold, offering a flat and smooth surface for efficient filtration, outstanding filtering performance due to precise slot spacing, robust mechanical properties ensuring longevity and reliability, high tensile strength, resistance to corrosion and rust, and excellent chemical stability for compatibility with various industrial environments.

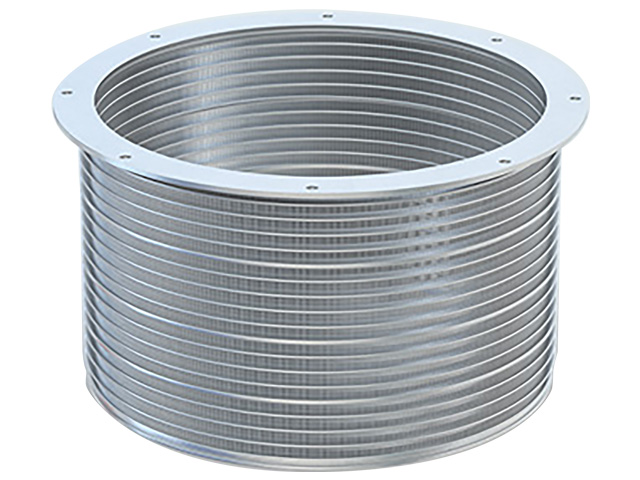

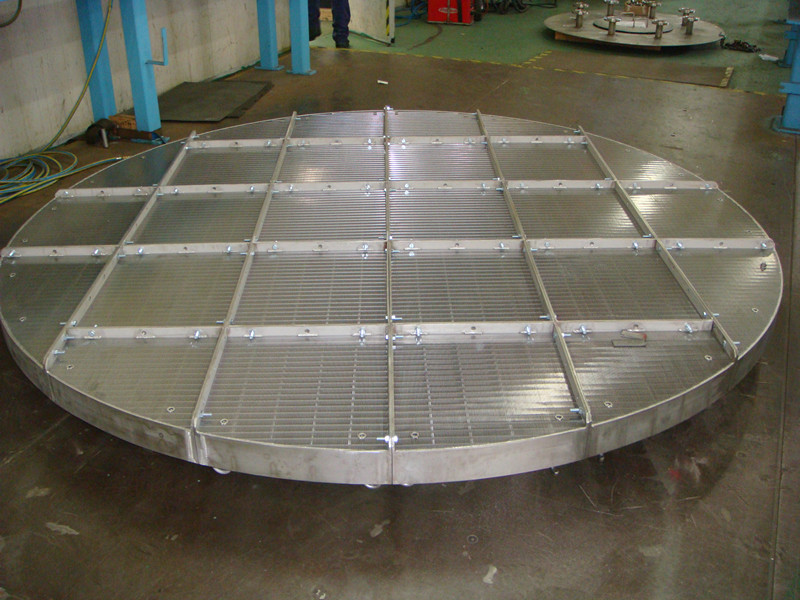

Wedge Wire Support Grids

Explore Multiwing, your trusted supplier of high-quality Wedgewire support grids. Our custom-engineered support grids are designed to optimize filtration and fluid processing systems in various industries, including water treatment, oil and gas, food and beverage, and more. Support grids are used for media retention and are widely employed in hydrogenation reactors, desulfurization reactors, molecular sieves, gas desulfurization reactions, and other essential systems due to their strength, durability, and flow rate.

With precision manufacturing and a commitment to quality, we deliver reliable support grids that enhance the efficiency and longevity of your filtration equipment. Our support grids are available in four categories: whole-type support grid, joint-type support grid, round space in the center of the support grid, and rectangular space in the center of the support grid.

The benefits of our support grids include a smooth surface, high open area, excellent capacity, temperature resistance, corrosion and rust resistance, high strength, long service life, and resistance to clogging. Explore our range of Wedgewire support grid solutions and discover how we can elevate your filtration processes.

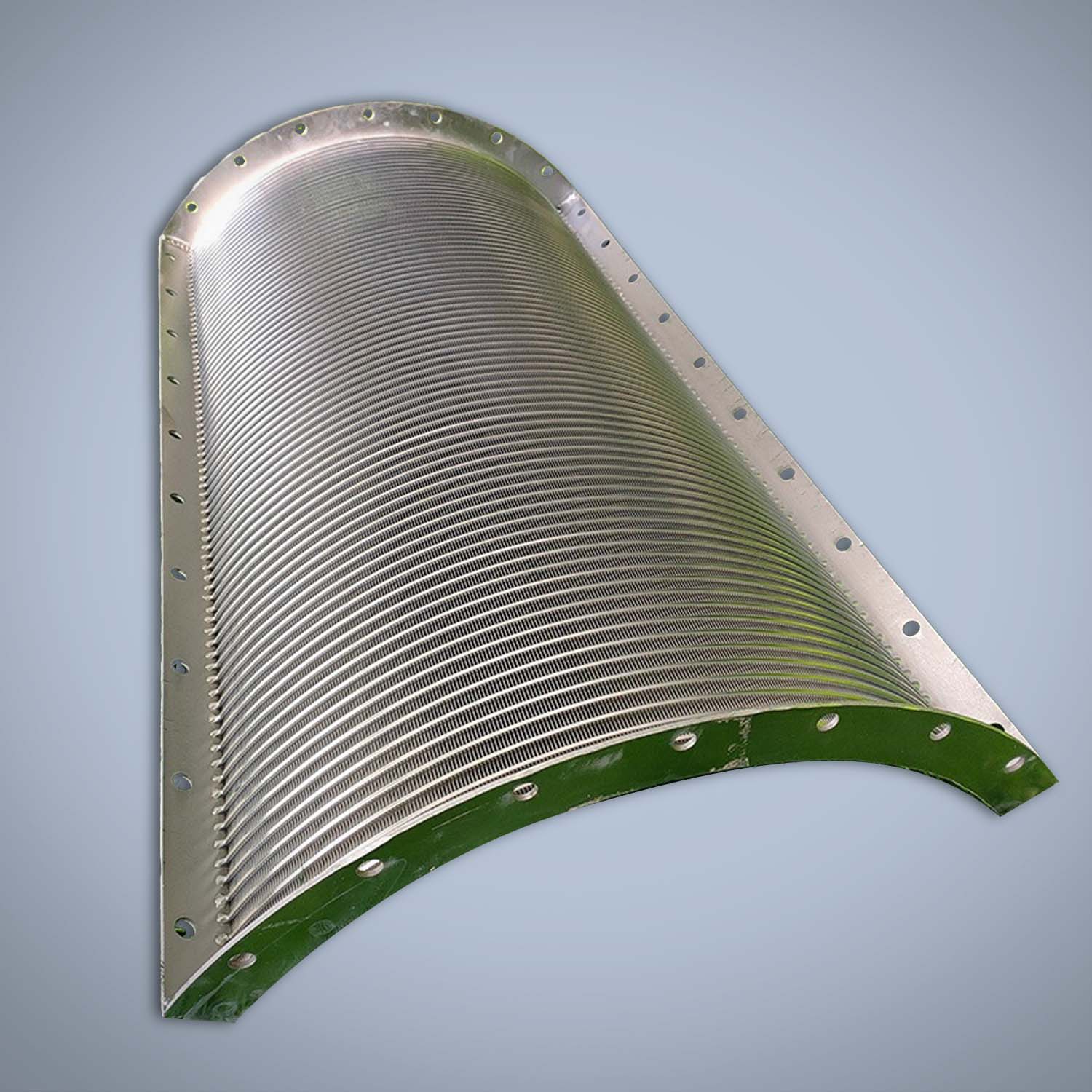

Sieve Bends Wedge Wire Screens

Explore Multiwing, a leading provider of high-quality Wedgewire Sieve Bends. Our Sieve Bends offer superior performance in solid-liquid separation, catering to diverse industries such as mining, aggregate processing, water treatment, and more. Designed with precision and durability, our Sieve Bends efficiently dewater and classify materials, ensuring optimal efficiency and cost-effectiveness in your operations.

Discover the benefits of our Wedgewire Sieve Bends, including exceptional screen accuracy, high capacity, corrosion resistance, and minimal maintenance requirements. Our customizable solutions are engineered to meet your specific application needs, delivering reliable performance even in the most demanding environments.

Sieve Bends are primarily used in coal preparation plants and mineral processing operations for dewatering, scalping, desliming, and recovery of graded slime, often coupled with water cyclones to effectively classify, dehydrate, desilt, and scalp fine materials.

Explore our range of Wedgewire Sieve Bends and experience how our innovative solutions can enhance your solid-liquid separation processes.

Wedge Wire Tube

Wedge wire tubes are high-performance filtration devices engineered from premium

stainless steel. They feature V-shaped profile wires that are precisely welded to

support rods in a cylindrical configuration, producing consistent slot openings ideal

for separating solids from liquids or gases. This robust design delivers excellent

strength, corrosion resistance, and durability for demanding industrial environments.

Customizable slot sizes, a non-clogging structure, and a smooth surface support

optimal flow, precise filtration, and easy cleaning, making wedge wire tubes suitable

for water and wastewater treatment, food and beverage processing, chemical

filtration, and environmental protection applications. Their solid construction ensures

a long operational life, minimal maintenance, reduced installation costs, and reliable

performance under intense pressure, offering both technical efficiency and economic

value for various process requirements.

Technical Information:

- Material: 304, 304L, 316, 316L, 321, 310S, Duplex steel, Super Duplex

stainless steel, Hastelloy, Titanium alloy, and more. Common products are

available from stock with competitive pricing and fast delivery. - Tube diameter: 0.5"–60". Larger diameters available on request.

- Tube length: 0.3 m, 0.6 m, 1 m, 2 m, 3 m, and 6 m. Special sizes can be

customized. - Slot size: 0.02 mm–2.5 mm or customized.

- Surface profile type: triangle wire.

- Support profile: triangular (V-shaped, wedge), round rod, flat bar, water-drop.

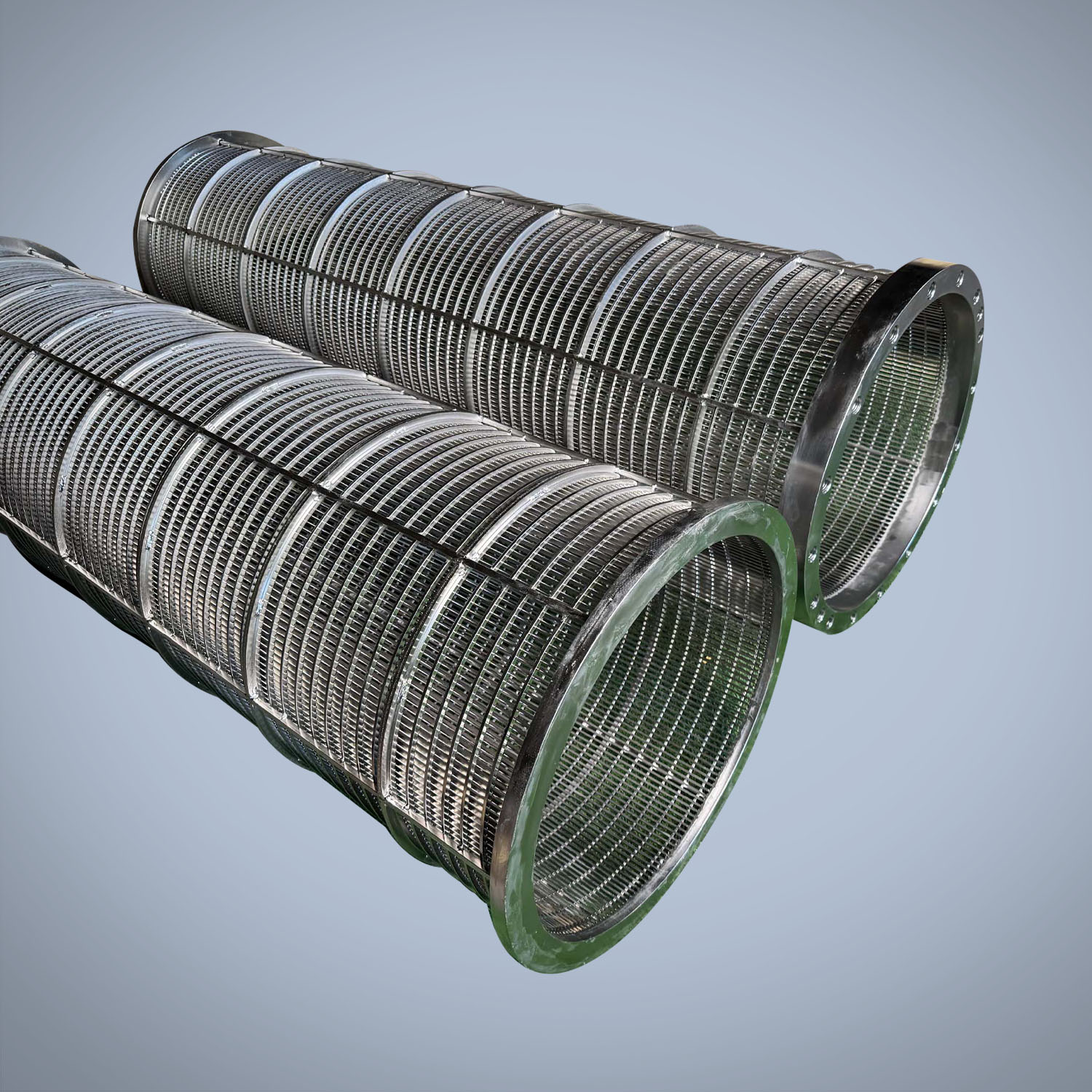

Wedge Wire Drum Screens

Wedge Wire Drum Screens are robust and efficient solutions for solid-liquid

separation, featuring a rotating cylindrical drum constructed from high-grade

materials and fitted with precision-engineered wedge-shaped wire profiles that create

highly uniform slot openings along the drum’s surface. As wastewater or process

liquids flow over or through the drum, suspended solids are retained on the exterior

or interior surface and automatically removed via integrated scrapers and washing

systems, while filtered water is continuously collected and discharged. With

customizable slot sizes ranging from 0.02 to 6.00 mm or Customized and drum

diameters up to 2400 mm, these screens support high capacity, low maintenance

requirements, corrosion resistance, and reliable operation under demanding

industrial and municipal conditions—making them ideal for applications such as

wastewater treatment, food processing, and environmental protection.

Technical Information:

- Materials: Stainless steel 304, 316L, 321, 310S; Duplex steel 2205, 2507

- Screen Diameter: Up to 2400 mm

- Screen Length: Up to 6000 mm

- Slot Sizes: Customized from 0.02 to 3.00 mm

- End Types: Flange or metal rings

Wedge Wire Sugar Screens

A wedge wire sugar screen is specially engineered to meet the rigorous needs of

sugar processing, using a smooth, precision-formed surface of V-shaped wires that

are expertly welded to create uniform and accurate slot openings. Available in

stainless steel, mild steel, duplex, and super duplex materials, this robust screen

delivers exceptional mechanical strength, high resistance to heat and corrosion, and

reliable long-term operation in challenging sugar mill environments. Designed to

efficiently separate sugar crystals from molasses and other liquids, the sugar screen

provides outstanding performance in centrifugal and DSM-type extraction, filtration,

and dewatering applications. Its customizable slot sizes and profile shapes, ranging

from cylindrical to arch or flat, allow for seamless integration into existing plant

systems, while the screen’s low maintenance needs and excellent abrasion

resistance ensure dependable, clog-resistant operation, optimizing throughput and

product quality while minimizing downtime and costs.

Wedge Wire Curved Screens

Our wedge wire curved screens are precision-engineered filtration and separation

solutions designed for durability, efficiency, and versatility, with fully customizable

curved profiles to suit specific project requirements. Available in stainless steel, mild

steel, duplex stainless steel, and super duplex stainless steel, these screens provide

the right balance of cost-effectiveness and superior corrosion resistance, even in the

toughest environments. With precision-welded construction for strength and

accuracy, they offer long service life, minimal maintenance, and consistent filtration

efficiency. Widely used in water and wastewater treatment, food and beverage

processing, pulp and paper manufacturing, mining, aggregates, dairy operations,

and seawater intake applications, our curved screens deliver reliable performance

across multiple industries.